What if you kept the “core” or the “essence” of a board the same throughout your designs and only changed the peripherals? You could build a range of products that had similar processing capabilities, but might be completely different products. By defining an abstraction layer at the edge of the core module you design, it’s possible to achieve efficiencies for your variety of products, including when those products are manufactured over time.

The above video is a talk given at the Zephyr meetup hosted by NXP at Embedded World North America in October of 2024. I focus on modular hardware design for scalability and adaptability. The Drachm (pronounced “dram”) module is something we have been regularly streaming on YouTube. This talk describes some of the motivations, the challenges of unconstrained designs, and how to build modular systems that take advantage of Zephyr RTOS capabilities.

Many SKUs, One Core

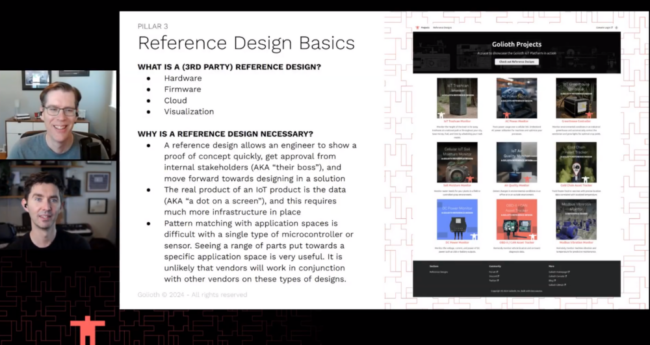

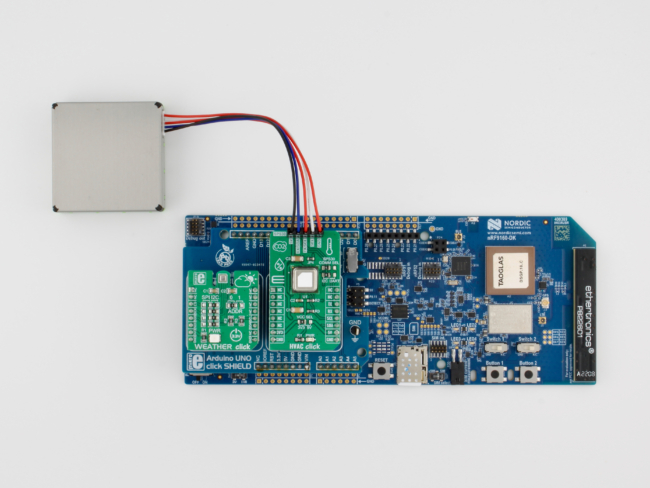

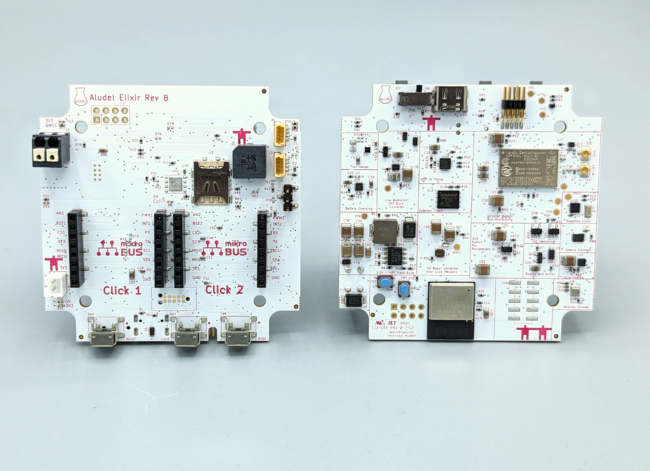

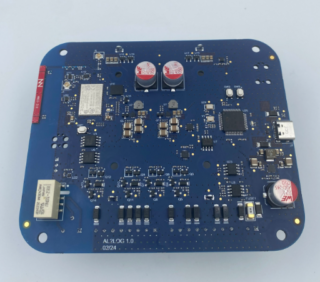

The Drachm module was conceived to be an extension of the Aludel Platform. We currently target a range of different verticals and end-applications with Golioth Reference Designs. But these are somewhat bulky: made to accept MikroBus Click boards, the case measures roughly 80 x 80 x 40 mm. What if we want to go smaller, but not re-design the board every time we have a new product idea?

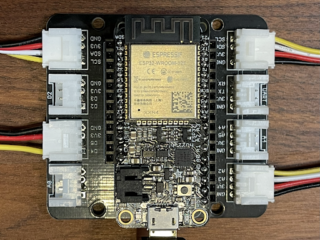

The Drachm module was meant to achieve this on multiple fronts. The castellated edge design would allow us to have a standard offering that covers a range of peripheral we want to hook up to the core module. But the module itself can change as well. The different versions of the Drachm module offer different capabilities of communication, processing power, and peripheral access on the underlying silicon. As in many modular systems, we trade off flexibility for an overall reduced feature set.

The Challenge of Hardware Changes

Modularity at the module connector edge benefits long term manufacturing as well. Building scalable IoT hardware requires constant adaptability. Component shortages, changing device requirements, and new tech trends demand flexible designs. Traditional methods, such as swapping processors or upgrading communications modules, can be tedious and impractical without a modular system.

How it works in Zephyr

This talk built on top of the article we published about abstract hardware interfaces in Zephyr. The key change is how we think of each component of the design. The module is being mounted to a carrier board, so it seems like a component of the carrier board’s BOM and software system. But in fact, we need to think about the carrier board as a “shield” (in Zephyr/Arduino) parlance, and instead map pins based on how we define the module edge (castellated pins). See the linked article on how to use predefined node labels and GPIO nexus nodes to achieve those ends.

Another key piece is that each module variant would need to maintain its own board files (Devicetree and Kconfig) to match up the pins on the castellated edge connection to the silicon onboard. The “analog input 1” pin on the drachm-1 variant (nRF9151 + ESP32-C3) would have a different mapping than the drachm-2 variant (nRF52480 + BG77), but to the parts on the shield / carrier board, it’d be all the same, since they only interface via the “analog input 1” nomenclature.

How it fits with Golioth

Golioth works great with customized hardware, which is subject to the harsh realities of sourcing. Engineers who need to redesign their hardware to upgrade or even just keep their production line running don’t want to re-do every aspect of their design, including firmware and cloud software. That’s why engineers are increasingly choosing Zephyr to target many hardware SKUs and why they’re choosing Golioth to help create a seamless experience for those variety of targets.

Using Golioth’s features like Blueprints, Tags, and our new OTA Cohorts capability an engineer could deliver different main firmware updates to boards using drachm-1 or drachm-n modules, but still have a consistent set of AI models being delivered to all eligible units. Golioth can also help to target different cohorts in your fleet to ensure the right updates are going to the right devices in the field.

Want to create a more resilient fleet? We can help! Our Solutions Engineering team can help to introduce more modularity and have a robust OTA strategy for your fleet. If you’re interested in doing it yourself but you’d like to talk through the options with Golioth team members, head over to our forum to start a conversation there.