The human body is surprisingly adept at sensing temperature. And so when I sat up in bed my body immediately informed me something was not right with my furnace. Yes, it’s winter in Wisconsin, but it shouldn’t feel that cold inside the house. The furnace was fine, but the thermostat was not, and so begins the story of how Golioth ran my furnace over Christmas.

Twas the Week Before Christmas and Cold in the House

I arose from my slumber and went to check the thermostat to find it displaying a message that it could not connect to the Equipment Interface Module (EIM). We have a furnace, air conditioner, and a heat recovery ventilator (HRV is a fancy name for a pair of fans that exchange stale inside air with fresh outside air). Being a geek, I wanted one way to control them all. That meant installing the Honeywell EIM to switch those subsystems. The thermostat then connects wirelessly to the EIM to provide automated control. But the chilly morning we’re discussing here, the thermostat wasn’t connecting at all!

After basic troubleshooting I used a jumper wire to short the white “run the furnace now” wire to the 24-volt red wire. The furnace kicked on and started warming up the house. There was nothing wrong with the furnace, but I no longer had an automatic way to control it.

But wait…industrial control is one place where Golioth shines! Could I use Golioth as my furnace controller until the built-in system was repaired?

Connecting the Golioth Greenhouse Controller to My House

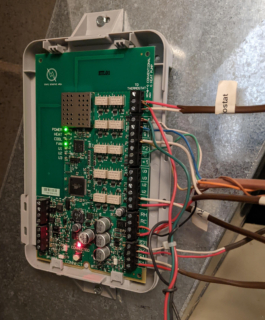

Just a week before this happened I wrote a blog post about the Golioth IoT Greenhouse Controller. It includes relays that can be switched automatically based on a temperature sensor. This is the definition of a thermostat. And these Golioth reference designs are built to be easily adaptable to similar applications. The hardware connection was dead simple: just run the red and white wires to the temperature-controlled relay on the greenhouse controller.

The logic in the firmware needed a quick tweak as greenhouses regulate temperature by taking action when it gets too hot (the opposite of heating a house). This required the “expert” firmware engineering step of changing a greater-than sign to a less-than sign. Luckily all of our reference designs have Over-the-Air (OTA) firmware update built-in so I was able to make this change while the device was in my basement, still connected to the furnace.

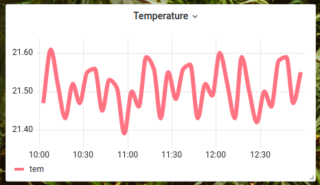

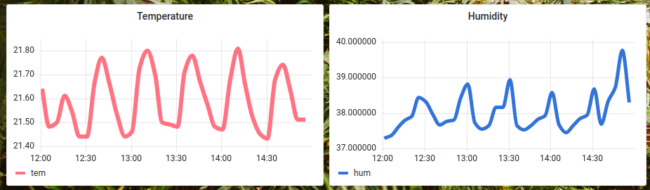

The temperature threshold is set via Golioth’s web console, so at that point I had actually upgraded my home system to include control from anywhere in the world! I also got a dashboard to keep my eye on temperature, pressure, and humidity.

Eating Your Own Dog Food (and Enjoying the Flavor)

So, why didn’t I just go out and buy another thermostat? The first reason is the ongoing chip shortage (now into it’s third year). The EIM part that was broken is about $80 normally, but there’s a 31 week lead time on it right now. The second reason is that the only wires running from the furnace to the thermostat are for supplying power (+24 V and Ground). Not only would a replacement thermostat be temporary, I would need to run new wires to give it furnace control or leave it in the basement.

For me this was a great philosophy experiment. We spend a lot of time planning and developing reference designs. Now I know a bit more about the user experience, and I like it! The hardware form-factor was easy to work with, and the approaches we take to control and feedback worked well for my application.

That doesn’t mean it was a perfect fit. Our basic design doesn’t have hysteresis built in, which means that the controller was trying to cycle more often than normal as there was no deadband to allow the house to warm (or cool) a bit past the target temperature. I implemented a simple cycle time threshold that prevented switching between on and off more than once in a 15 minutes period. It’s an application-specific topic that could be added to an implementation guide for this reference design.

I called several HVAC shops in town and the earliest estimates for a new part was the end of March. Online I was able to find a Honeywell “starter” kit included the replacement EIM with just a week before delivery. During this time the Golioth-controlled furnace kept the house warm, but also getting very very humid without the HRV to help regulate. Good news everyone, the Greenhouse demo has a humidity sensor and a second relay. You guessed, it. I added control for the ventilation as well!

I Built An IoT Thermostat in 20 Minutes

Now, I was already familiar with this demo unit, so take this with a grain of salt. But the purpose of the Golioth reference designs is to give businesses a running start when developing a proof of concept. I was able to substitute this one in place of my thermostat with just about 20 minutes of effort. It kept my house comfortable in the harshest conditions of December’s arctic blast, and it let me check temperature and adjust settings while I was working outside of the home during that time. This is the Internet of Things, and it’s never been easier.

No comments yet! Start the discussion at forum.golioth.io